CU Series Free Mount Cylinder With Air Cushion – Xi Lanh Khí Nén SMC

Product Description

– Xi Lanh Khí Nén SMC

Air cylinder that adopts a new air cushion mechanism.

[Features]

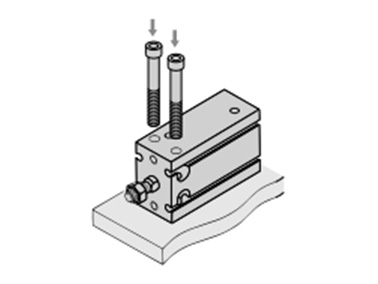

· Multiple-surface direct mounting with a square body and no brackets lets you freely choose the mounting surface.

· This enables space-saving designs for equipment.

· Slightly extended dimensions relative to the CU standard models.

· There is no protrusion of the cushion valve, and the width is the same.

· 3 types of mounting orientations can be accommodated according to the installation conditions.

· Approximately 2.4 times more allowable kinetic energy.

· Improved sound insulation (reduced impact of noise at the stroke end).

· Interchangeable mounting.

Download

CU Series Free Mount Cylinder With Air Cushion – Xi Lanh Khí Nén SMC

| Model | Pneumatic (non-lube) type |

|---|---|

| Fluid | Air |

| Proof Pressure | 1.0 MPa |

| Maximum operating pressure | 0.7 MPa |

| Minimum operating pressure | 0.08 MPa |

| Ambient and Fluid Temperature | Without auto switch: -10°C to +70 ℃ (no freezing) |

| With auto switch: -10°C to +60 ℃ (no freezing) | |

| Rod-end thread | Male thread |

| Stroke Length Tolerance | 0 to +1.0 |

| Operating piston speed | 50 to 500 mm/s |

Effective Cushion Length

- Bore size 20 mm: effective cushion length 6.6 mm

- Bore size 25 mm: effective cushion length 6.7 mm

- Bore size 32 mm: effective cushion length 7.7 mm

Standard Stroke Table

Bore size 20 mm, 25 mm, 32 mm: standard stroke 20 mm, 30 mm, 40 mm, 50 mm, 60 mm, 70 mm, 80 mm, 90 mm, 100 mm

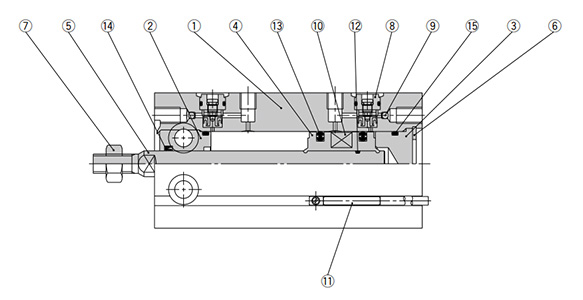

Diagram

Diagram: CU Series

| Number | Part Name | Material | Quantity | Notes |

|---|---|---|---|---|

| 1 | Cylinder Tube | Aluminum alloy | 1 | Hard anodized aluminum |

| 2 | Rod cover | Aluminum alloy | 1 | Hard anodized aluminum |

| 3 | Head cover | Aluminum alloy | 1 | Chromate |

| 4 | Piston | Aluminum alloy | 1 | Chromate |

| 5 | Piston rod | Stainless steel | 1 | – |

| 6 | Retaining Ring | Carbon tool steel | 1 | Phosphate conversion coating |

| 7 | Rod end nut | Carbon steel | 1 | Chromate |

| 8 | Cushion needle assembly | – | (2) | – |

| 9 | Steel ball | Carbon steel | 2 | – |

| 10 | Magnet | – | 1 | – |

| 11 | Auto switch | – | (2) | – |

| 12 | Piston gasket | NBR | 1 | – |

| 13 | Piston packing | NBR | 2 | – |

| 14 | Rod packing | NBR | 1 | – |

| 15 | Gasket | NBR | 1 | – |

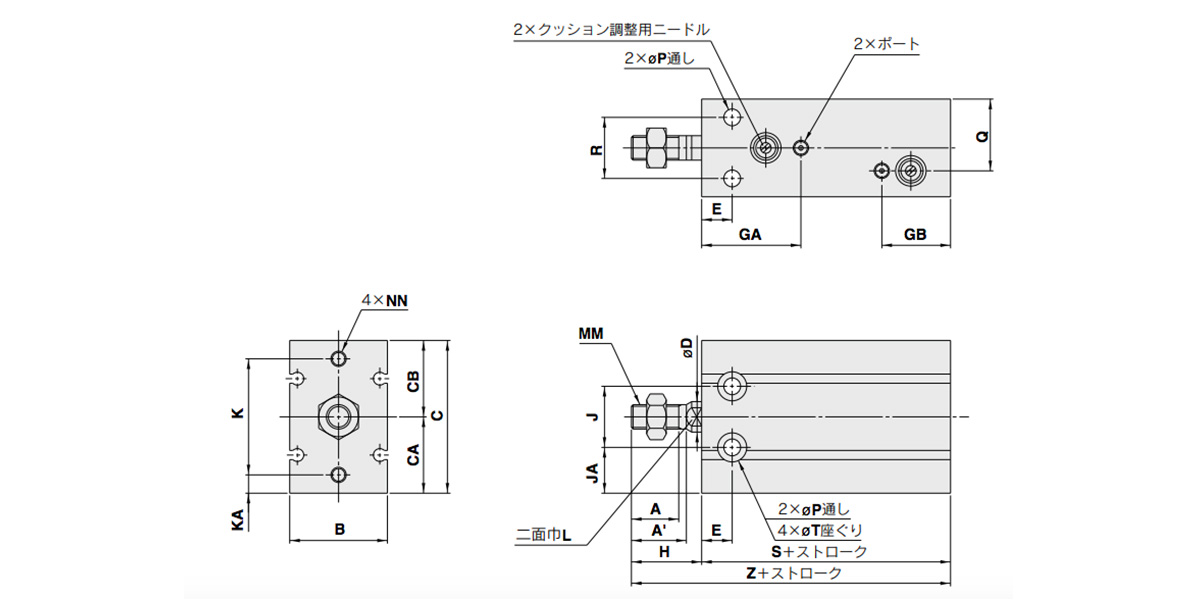

Drawing

Dimensional drawings: CU Series Free Mount Cylinder With Air Cushion

(Units: mm)

| Tube inner diameter (mm) |

Port | A | A’ | B | C | CA | CB | D | E | GA | GB | H | J | JA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | M5 × 0.8 | 12 | 14 | 26 | 42 | 20 | 22 | 8 | 9 | 29 | 27 | 19 | 16 | 12 |

| 25 | M5 × 0.8 | 15.5 | 18 | 32 | 50 | 25 | 25 | 10 | 10 | 32.5 | 22.5 | 23 | 20 | 15 |

| 32 | 1/8 | 19.5 | 22 | 40 | 62 | 31 | 31 | 12 | 11 | 35 | 25 | 27 | 24 | 19 |

(Units: mm)

| Tube inner diameter (mm) |

K | KA | L | MM | NN | P | Q | R | T | S | Z | Standard Stroke |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 30 | 5 | 6 | M6 × 1.0 | M5 × 0.8 depth 8 | 5.5 | 13 | 16 | 9.3 depth 8 | 53 | 72 | 20, 30, 40, 50, 60, 70, 80, 90, 100 |

| 25 | 38 | 6 | 8 | M8 × 1.25 | M5 × 0.8 depth 8 | 5.5 | 23.5 | 20 | 9.3 depth 9 | 51.5 | 74.5 | |

| 32 | 48 | 7 | 10 | M10 × 1.25 | M6 × 1.0 depth 9 | 6.6 | 29 | 24 | 11 depth 11.5 | 56 | 83 |

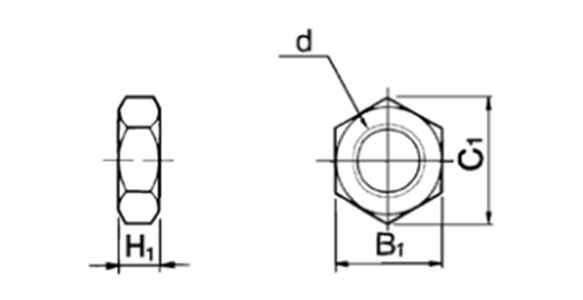

Dimensional drawings: rod-end nut / accessory

(Units: mm)

| Part No. | Applicable Tube Bore Size (mm) |

d | H1 | B1 | C1 |

|---|---|---|---|---|---|

| NT-015A | 20 | M6 × 1.0 | 5 | 10 | 11.5 |

| NT-02 | 25 | M8 × 1.25 | 5 | 13 | 15.0 |

| NT-03 | 32 | M10 × 1.25 | 6 | 17 | 19.6 |

Material: carbon steel

Proper Auto Switch Mounting Position (Detection at Stroke End) and Mounting Height

(Units: mm)

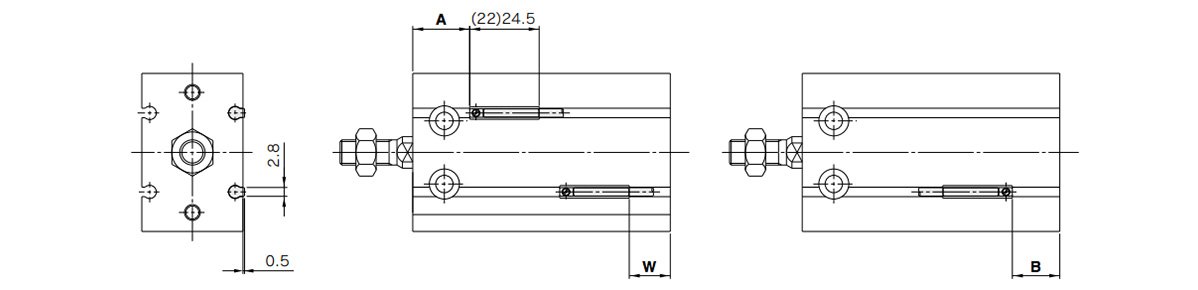

Dimensional drawings: D-A9□/D-M9□/D-M9□W/D-M9□A

*( ): denotes the values of D-A96.

(Units: mm)

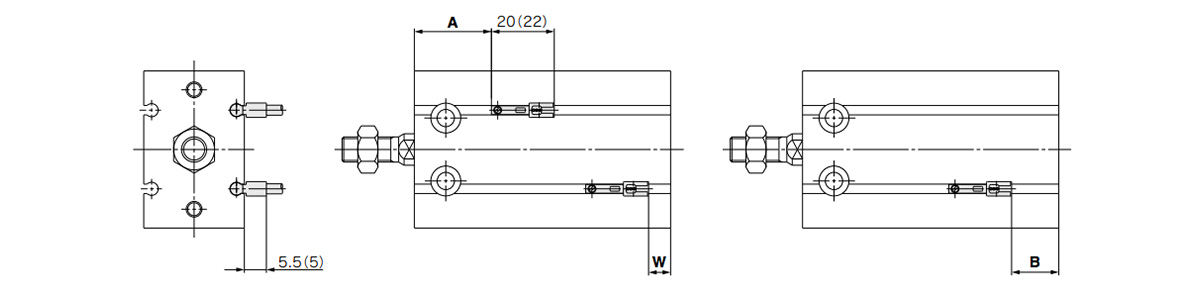

Dimensional drawings: D-A9□V/D-M9□V/D-M9□WV/D-M9□AV

*( ): denotes the values of D-M9□V/D-M9□WV.

(Units: mm)

| Tube inner diameter (mm) |

D-A9□, D-A9□V | D-M9□, D-M9□W | D-M9□V, D-M9□WV | D-M9□A | D-M9□AV | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | W | A | B | W | A | B | W | A | B | W | A | B | W | |

| 20 | 18 | 15 | 13 (10.5) | 22 | 19 | 9 | 22 | 19 | 11 | 22 | 19 | 11 | 22 | 19 | 13 |

| 25 | 20 | 11 | 9 (6.5) | 24.5 | 15 | 5 | 24.5 | 15 | 7 | 24.5 | 15 | 7 | 24.5 | 15 | 9 |

| 32 | 22.5 | 13.5 | 11.5 (9) | 26.5 | 17.5 | 7.5 | 26.5 | 17.5 | 9.5 | 26.5 | 17.5 | 9.5 | 26.5 | 17.5 | 11.5 |

- *1Figures in the table above are used as a reference when mounting the auto switches for stroke end detection. When actually setting the auto switches, adjust them after confirming their operation.

- *2Values in ( ) under column W are dimensions for the D-A90 and D-A93 type.

Operating Range

D-A9□, D-A9□V

Bore size 20 mm: 11 mm / Bore size 25 mm: 12.5 mm / Bore size 32 mm: 14 mm

D-M9□, D-M9□V, D-M9□W, D-M9□WV, D-M9□A, D-M9□AV

Bore size 20 mm: 7 mm / Bore size 25 mm: 7 mm / Bore size 32 mm: 7.5 mm

*The operating range is provided as a guideline that includes hysteresis and is not a guaranteed value (assuming approximately ±30% dispersion). It may vary substantially depending on the ambient environment.

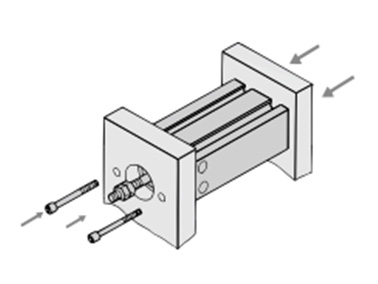

Mounting

Axial mounting (body tapped)

Vertical mounting (body through-holes)

Lateral mounting (body through-holes)

Precautions

Installation and Removal of Retaining Rings

- *Use an appropriate pair of pliers (tool for installing a type C retaining ring) for installation and removal of retaining rings.

- *Even when using an appropriate pair of pliers (tool for installing a type C retaining ring), proceed with caution as there is a danger of the retaining ring flying off the end of the pliers (tool) and causing bodily injury or damage to nearby equipment. After installation, make sure that the retaining ring is securely seated into the retaining ring groove before supplying air.

Selection

- *Operate the cylinder to the stroke end. When the stroke is restricted by an external stopper or a clamped workpiece, sufficient cushioning and noise reduction may not be achieved.

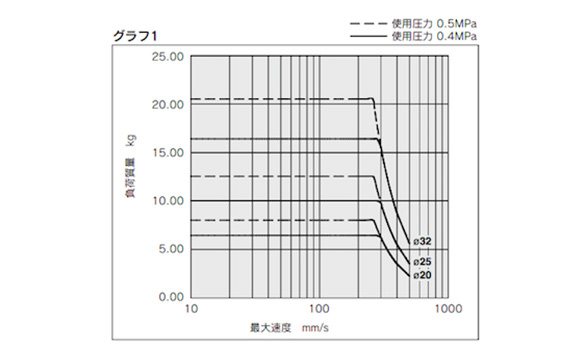

- *Strictly observe the limiting ranges for load weight and maximum speed (Graph 1). Also, the limiting ranges provided here are based on the condition that the cylinder is operated to the stroke end with proper cushion needle adjustment. If operated beyond the limiting ranges, excessive impact will occur and this may cause damage to equipment.

Limiting ranges for load weight and maximum speed (Graph 1)

*See the manufacturer’s catalog for product information other than that detailed above.

Basic Information

| Cylinder Operation Method | Double Acting | Rod Operation Method | Single Rods | Main Body Shape | Plate Cylinder |

|---|---|---|---|---|---|

| Additional Function | Standard | Environment, Applications | Standard | End Locking | No |

| Valves | No | Operating Pressure(MPa) | 0.08::0.7 |

CDU20-20A-A93

CDU20-20A-A93L

CDU20-20A-A93LS

CDU20-20A-A93S

CDU20-20A-A93V

CDU20-20A-A93VLS

CDU20-20A-A96

CDU20-20A-M9B

CDU20-20A-M9BAL

CDU20-20A-M9BAS

CDU20-20A-M9BL

CDU20-20A-M9BS

CDU20-20A-M9BV

CDU20-20A-M9BVLS

CDU20-20A-M9BVS

CDU20-20A-M9BVZ

CDU20-20A-M9BW

CDU20-20A-M9BWL

CDU20-20A-M9BWM

CDU20-20A-M9BWSDPC

CDU20-20A-M9N

CDU20-20A-M9NL

CDU20-20A-M9NS

CDU20-20A-M9NV

CDU20-20A-M9NW

CDU20-30A

CDU20-30A-A93

CDU20-30A-A93L

CDU20-30A-A93LS

CDU25-20A-A90

CDU25-20A-A93L

CDU25-20A-M9BL

CDU25-20A-M9BS

CDU25-20A-M9BVL

CDU25-20A-M9BW

CDU25-20A-M9BWL

CDU25-20A-M9BWV

CDU25-20A-M9NL

CDU25-20A-M9NW

CDU25-30A

CDU25-30A-A93

CDU25-30A-A93L

CDU25-30A-A93LS

CDU25-30A-M9B

CDU25-30A-M9BAL

CDU25-30A-M9BL

CDU25-30A-M9BV

CDU25-30A-M9BVL

CDU25-30A-M9BW

CDU25-30A-M9BWLS

CDU25-30A-M9PL

CDU25-40A

CDU25-40A-A90

CDU25-40A-A93

CDU25-40A-A93L

CDU25-40A-A93LS

CDU25-40A-M9B

CDU25-40A-M9BL

CDU32-20A-A93

CDU32-20A-A93L

CDU32-20A-A93VL

CDU32-20A-A93VLS

CDU32-20A-M9B

CDU32-20A-M9BL

CDU32-20A-M9BW

CDU32-20A-M9BWL

CDU32-20A-M9NWVL

CDU32-30A

CDU32-30A-A93S

CDU32-30A-A93VLS

CDU32-30A-M9BAL

CDU32-30A-M9BL

CDU32-30A-M9BLS

CDU32-30A-M9BV

CDU32-30A-M9BW

CDU32-30A-M9BWL

CDU32-30A-M9BWS

CDU32-30A-M9BWSDPC

CDU32-30A-M9BWVL

CDU32-30A-M9NWL

CDU32-40A

CDU32-40A-A93L

CDU32-40A-A93VL

CDU32-40A-M9B

CDU32-40A-M9BL

CDU32-40A-M9BWL

CDU32-40A-M9N