Compact Cylinder, Anti-Lateral Load Type CQS□S Series – Xi Lanh Khí Nén SMC

Product Description

– Xi Lanh Khí Nén SMC

Compact Cylinder, Anti-Lateral Load Type CQS□S Series that is ideal for machine designs with small space requirements.

[Features]

· Square body shape that gives you flexibility for designing machines.

· Auto switch mounting direction allows for flexible design requirements.

· 2-way basic mounting.

· Non-rotating rod with high non-rotating accuracy.

Download

Compact Cylinder, Anti-Lateral Load Type CQS□S Series Details – Xi Lanh Khí Nén SMC

Compact Cylinder, Anti-Lateral Load Type CQS□S Series product image

Compact Cylinder, Anti-Lateral Load Type CQS□S Series Specifications

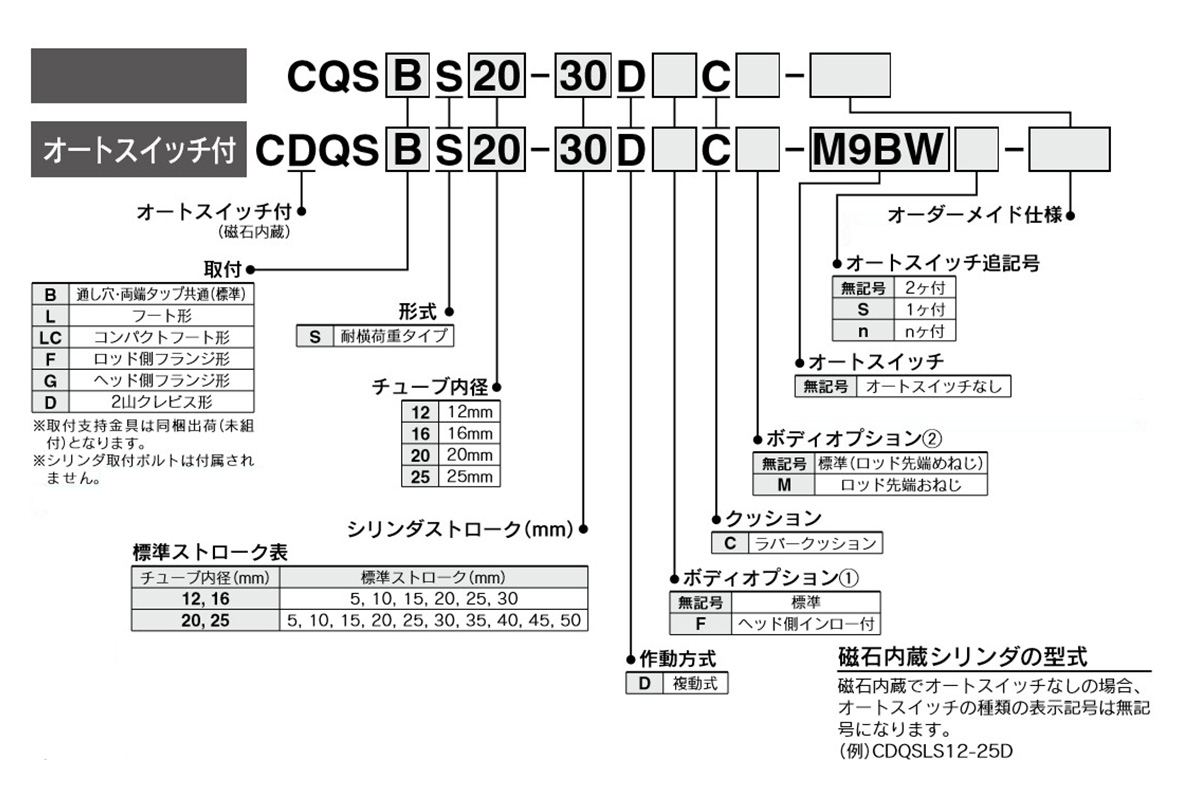

Model Number Notation

Model number example

Individual Made-to-Order Specifications

| Indicator symbol | Specifications/contents |

|---|---|

| -X271 | Fluororubber seals |

Made to order specifications

| Indicator symbol | Specifications/contents |

|---|---|

| -XC6 | Piston rod, retaining ring, rod-end nut made of stainless steel |

| -XC85 | Grease for food processing equipment |

Standard specification

| Tube Internal Diameter (mm) | 12 | 16 | 20 | 25 |

|---|---|---|---|---|

| Operating method | Double acting, single rod | |||

| Applicable fluids | Air | |||

| Lubrication | Not required (non-lube) | |||

| Proof pressure | 1.5 MPa | |||

| Maximum operating pressure | 1.0 MPa | |||

| Minimum operating pressure | 0.07 MPa | 0.05 MPa | ||

| Ambient and working fluid temperature | Without auto switch: -10°C to 70°C (No freezing) | |||

| With auto switch: -10°C to 60°C (No freezing) | ||||

| Cushioning | Rubber bumper* | |||

| Rod-end thread | Female thread | |||

| Stroke length tolerance | +1.0 mm* 0 |

|||

| Operating piston speed | 50 to 500 mm/s | |||

| Allowable kinetic energy J | 0.043 | 0.075 | 0.11 | 0.18 |

- *Stroke length tolerance does not include the amount of bumper change.

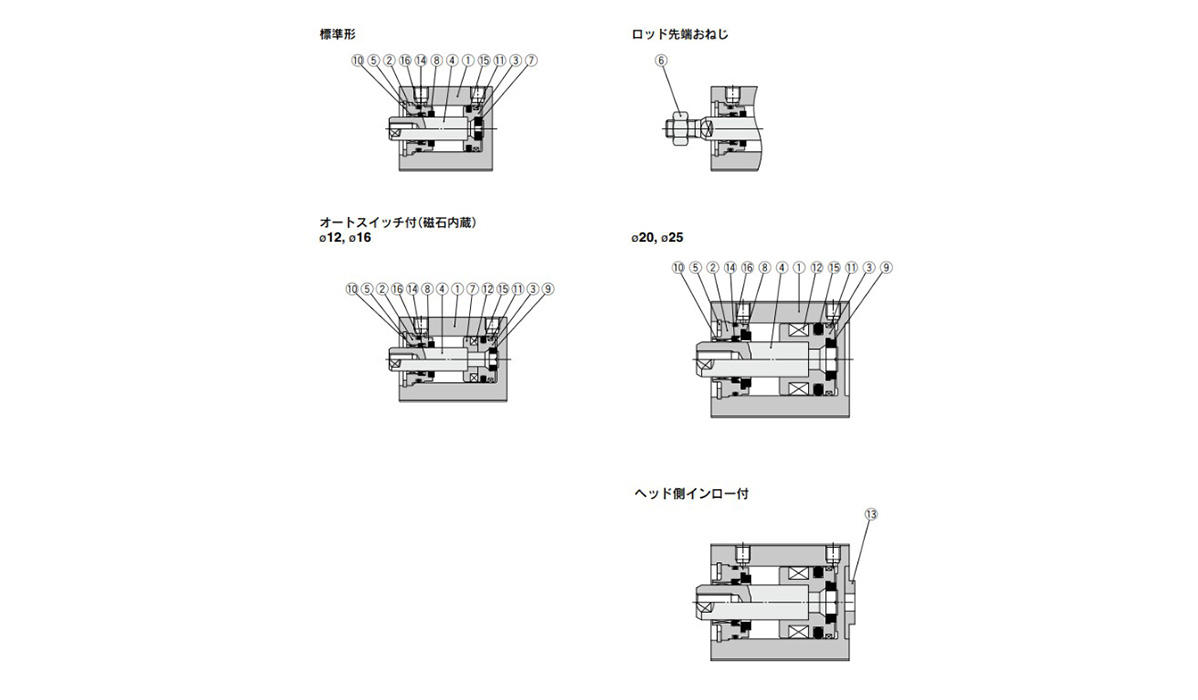

Structural drawing

Compact Cylinder, Anti-Lateral Load Type CQS□S Series Structural Drawing

Component Parts

| Number | Part name | Material | Note |

|---|---|---|---|

| 1 | Cylinder tube | Aluminum Alloy | Hard Anodize |

| 2 | Collar | Aluminum Alloy | Anodized |

| 3 | Piston | Aluminum Alloy | – |

| 4 | Piston rod | Stainless steel | – |

| 5 | Retaining Ring | Carbon tool steel | Phosphate coated |

| 6 | Rod-end nut | Carbon steel | Zinc chromate |

| 7 | Spacer for switch type | Aluminum Alloy | Chromate |

| 8 | Bumper A | Urethane | – |

| 9 | Damper B | Urethane | – |

| 10 | Bushing | Oil-impregnated sintered alloy | – |

| 11 | Wear ring | Resin | – |

| 12 | Magnet | – | – |

| 13 | Centering location ring | Aluminum Alloy | Anodized |

| *14 | Rod Gasket | NBR | – |

| *15 | Piston Gasket | NBR | – |

| *16 | Tube gasket | NBR | – |

Replacement Parts / Seal Kit

| Tube Internal Diameter (mm) | Order number | Content |

|---|---|---|

| 12 | CQSB12-PS | Set of above numbers (14), (15), (16) |

| 16 | CQSB16-PS | |

| 20 | CQSB20-PS | |

| 25 | CQSB25-PS |

- *Seal kit includes (14), (15) and (16). Order the seal kit based on each bore size.

- *The seal kit does not include a grease pack, so please order a grease pack separately.

- *Grease pack part number: GR-S-010 (10 g)

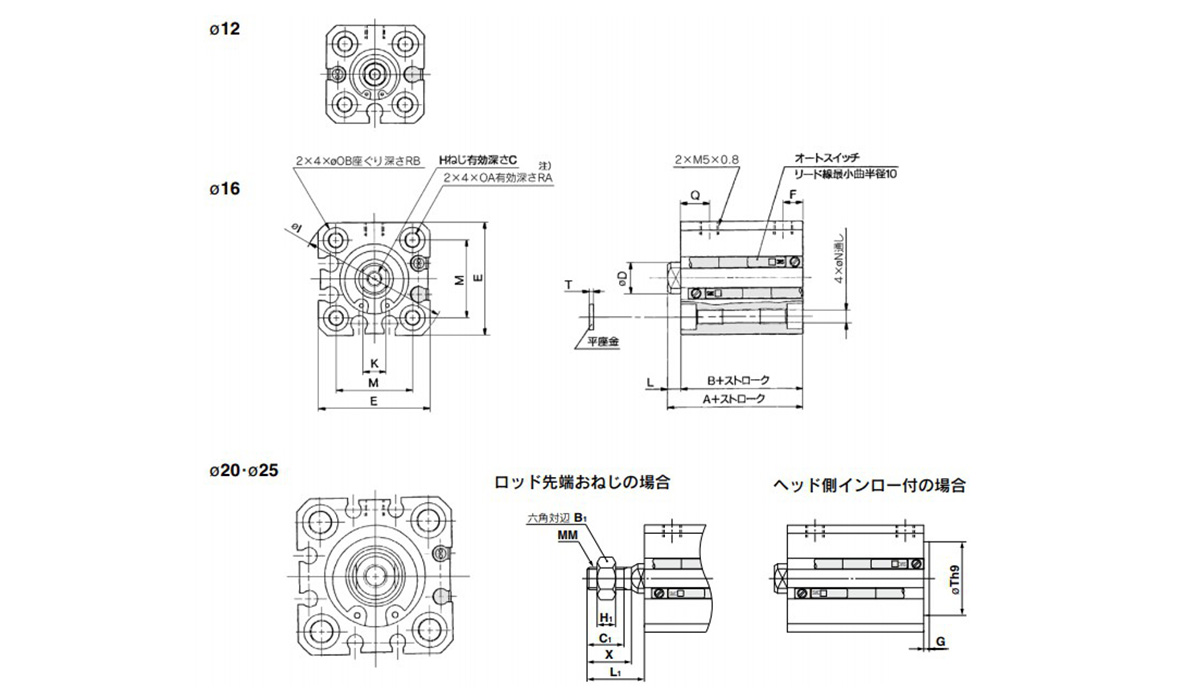

Compact Cylinder, Anti-Lateral Load Type CQS□S Series Example Dimensions

(Unit: mm)

Standard type (through-hole / both ends tapped common): CQSBS/CDQSBS dimensional drawing

Male rod end

(Unit: mm)

| Tube Internal Diameter (mm) | B1 | C1 | H1 | L1 | MM | X |

|---|---|---|---|---|---|---|

| 12 | 8 | 9 | 4 | 14 | M5 × 0.8 | 10.5 |

| 16 | 10 | 10 | 5 | 15.5 | M6 × 1.0 | 12 |

| 20 | 13 | 12 | 5 | 18.5 | M8 × 1.25 | 14 |

| 25 | 17 | 15 | 6 | 22.5 | M10 × 1.25 | 17.5 |

With Boss on Head End

(Unit: mm)

| Tube Internal Diameter (mm) | G | Th9 |

|---|---|---|

| 12 | 1.5 | 15 (-0.043 to 0) |

| 16 | 1.5 | 20 (-0.052 to 0) |

| 20 | 2 | 13 (-0.043 to 0) |

| 25 | 2 | 15 (-0.043 to 0) |

- *Note) With boss on rod end: option. (Suffix -XC36 to the end of the part number.)

Note that only bore sizes ø12 (12‑mm diameter) and ø16 (16‑mm diameter) are applicable.

Standard type

(Unit: mm)

| Bore size (mm) |

Stroke range (mm) |

Without auto switch | With auto switch | C | D | E | F | H | I | K | L | M | N | OA | OB | Q | RA | RB | T | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | A | B | ||||||||||||||||||

| 12 | 5 to 30 | 25.5 | 22 | 30.5 | 27 | 6 | 6 | 25 | 5 | M3 × 0.5 | 32 | 5 | 3.5 | 15.5 | 3.5 | M4 × 0.7 | 6.5 | 7.5 | 7 | 4 | 0.5 |

| 16 | 5 to 30 | 25.5 | 22 | 30.5 | 27 | 8 | 8 | 29 | 5 | M4 × 0.7 | 38 | 6 | 3.5 | 20 | 3.5 | M4 × 0.7 | 6.5 | 7.5 | 7 | 4 | 0.5 |

| 20 | 5 to 50 | 29 | 24.5 | 39 | 34.5 | 7 | 10 | 36 | 5.5 | M5 × 0.8 | 47 | 8 | 4.5 | 25.5 | 5.4 | M6 × 1.0 | 9 | 8 | 10 | 7 | 1 |

| 25 | 5 to 50 | 32.5 | 27.5 | 42.5 | 37.5 | 12 | 12 | 40 | 5.5 | M6 × 1.0 | 52 | 10 | 5 | 28 | 5.4 | M6 × 1.0 | 9 | 9 | 10 | 7 | 1 |

- *Note) For the following bore/stroke sizes, the through-hole is threaded: Standard type: ø20 (20‑mm diameter) 5 to 10 stroke and ø25 (25‑mm diameter) 5 stroke.

Basic Information

| Cylinder Operation Method | Double Acting | Rod Operation Method | Single Rods | Main Body Shape | Plate Cylinder |

|---|---|---|---|---|---|

| Additional Function | High rigidity / high precision high class guide | Environment, Applications | Standard | Cushion | Rubber cushion |

| Type | Anti-lateral load type |

CDQSBS12-5DC-A90VLS

CDQSBS16-5DC-A93VLS

CDQSBS20-5DC-A93VLS

CDQSBS25-5DC-A93VLS